Features of binary power generation

Microbinary is the world's first semi-sealed screw turbine type, highly efficient and compact binary power generation system born from the world's best screw compressor technology owned by Kobe Steel.

Microbinary is a power generation system that can save energy, reduce power peak cuts, and is suitable for constructing small-scale green power generation.

There are 2 types of Microbinary power generation. The first type is a "hot water based microbinary" which can generate electricity of up to 72 kW (power generation end load) with hot water of 70 to 95 C as a heat source. The second type is "steam based microbinary" which can generate electricity up to 125 kW using steam of 110 to 130 C as the main heat source.

The world's first highly efficient small binary power generation system with semi-sealed screw turbine

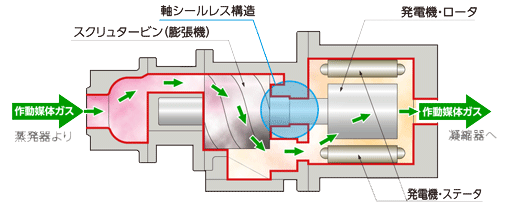

By integrating the screw turbine and generator rotor into a single shaft structure, we eliminated shaft seals, couplings and generator bearings and achieved a structure that prevents working fluids from leaking.

The world's first operating small binary power generation system with semi-sealed screw turbine guarantees stable operation over a long period of time.

Structure of semi-sealed screw turbine type generator

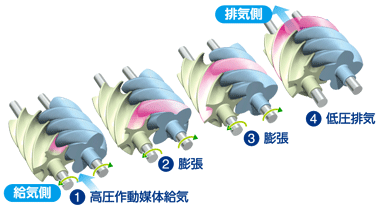

Moreover, the screw turbine adopted here is developed from the basis of the world's leading compressor and refrigerator technology which has been cultivated over many years, thus resulting in its resistance to fluctuation of heat source and highly efficient power generation.

Furthermore, by utilizing mass-production technology of refrigerator and heat pump to share parts and save costs, "All-in-one" microbinary can be optimized to the condition of heat source and the installation environment while enabling space saving at the same time.

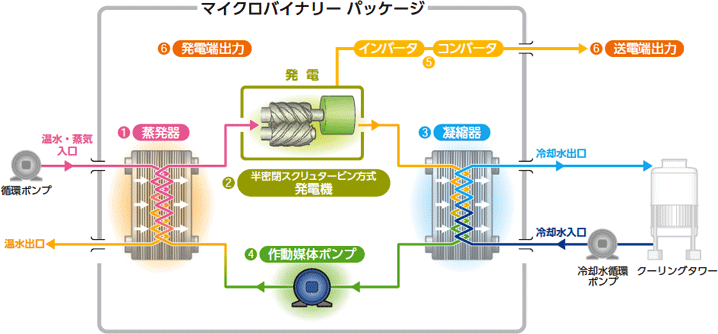

Power generation system flow

ฆ1 The exit temperature is carried on.

ฆ2 Depending on various conditions, the entrancefs temperature difference may vary.

ฆ1 The exit temperature is carried on.

ฆ2 Depending on various conditions, the entrancefs temperature difference may vary.

Binary cycle power generation method

Heat from geothermal fluids heats up and evaporates the working medium with a low boiling point, turning the turbine with the saturated vapour generate electricity. There are 2 cycles within the power generation system: the primary cycle that contains the geothermal fluid, and a secondary cycle where the organic working fluid is enclosed, hence the name ebinaryf. Because it can generate electricity using low boiling point working medium, even the lowest level of energy can be fully utilized to generate electricity.Working fluids

Microbinary uses the organic medium HFC245fa as a working medium. HFC245fa is an incombustible inert gas with an ozone depletion potential (ODP) of 0 resulting in less environmental burden. The hot water binary MB-70H, using an inert gas as a working medium, meets the specifications for deregulation of compact binary power generation of the Electricity Business Law.Functions of components in the unit

| 1 Evaporator | A plate type heat exchanger with high exchange rate that evaporates the working fluids by geothermal fluids (steam / hot water) heat. |

| 2 Semi-sealed screw turbine type generator | Generate electricity by turning the screw turbine (= generator rotor) with evaporated vapour from working medium. Microbinary adopts the worldfs first semi-sealed type screw turbine generator. In addition, the generator is also equipped with a highly efficient IPM generator. |

| 3 Condenser | A heat exchanger that liquefies working medium vapour with cooling fluids. Similar to the evaporator, condensers are also equipped with a plate type heat exchanger with high exchange rate |

| 4 Working fluid pump | A shaft without seal pump that sends working medium to the evaporator. It is automatically controlled to maintain optimum power generation performance. |

| 5 Inverter/converter | Inverters apply brakes on the generators, directing generated electricity into Direct Current while controlling the rotation speed. Converters direct the DC electricity from the inverters to the national grid (commercial power supply). |

| 6 Generator end output / transmission end output | The power transmission end output is the net power generation output of the unit which is the result of subtracting the power consumed in the unit such as the refrigerant pump from the output (power generation end output) generated by the generator. |