Operation technology of geothermal power generation

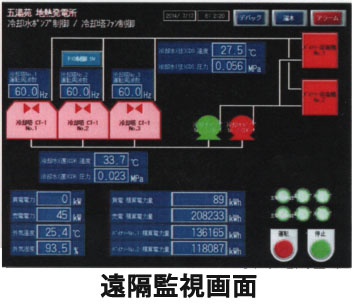

Remote monitoring

The operation of the Goiyuen Geothermal Power Plant and Yuyama Geothermal Power Plant is entirely automated. Data necessary for operating generators is gathered from cubicles in the power plant and displayed on an LCD terminal called GOT (Graphic Operation Terminal). Furthermore, the same information can be accessed and displayed on the headquarters’ monitors via Internet. Additionally, since there are monitoring web camera installed, the condition of the power station can be monitored through computers or mobile phones.

Daily record

Data on generating end power of the generator, hot water ・ cooling water inlet / outlet temperature, etc. are logged in an SD card in the generator main unit every minute. This data can be acquired either by removing the SD card whenever the generator is turned off, or as CSV data retrieved via FTP. Other than that, records of data on the remote monitoring screen are also handwritten on a daily basis. All of these efforts provide valuable insights and information for those of interest.

Procedures when trouble occurs

When a malfunction occurs in the power generation facility, emergency warning mails are sent to all concerned parties at the same time. Responding to a sudden emergency early in the morning, late at night is extremely cumbersome and challenging, therefore daily inspection and maintenance is always prioritized to prevent such scenarios.

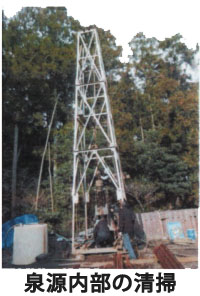

Planned steam amount and actual steam amount

The numerical values ??of Goiyuen measured at the time of planning were: Total pressure 1,940 Pa; static pressure 340 Pa; dynamic pressure 1,600 P; temperature 125 ° C. However, depending on the season, climate (rainy weather), time of the day, slight fluctuations can be observed, especially during the cold season, early morning and after the rain, the temperature changes (within 3 ° C) ・ steam pressure tends to be slightly lower. In addition, it is inevitable that chemical components in hot springs would accumulate inside the steam well over the years, resulting in gradual decrease in vapor pressure. Regular cleanups are required to neutralize crystallization.

In a large-scale geothermal power plant, power generation capacity is planned to be about 50% of the measured steam amount, while in small-scale power generation, facilities are reasonably designed with a generation capacity of 20 to 30% of the measured steam amount.

Water quality of cooling water

In the condenser that liquefies the vaporized working medium, 4,000 liters of cooling water circulate per minute. At Goiyuan and Yuyama, about 50 tons of cooling water per day is required for evaporation of circulating cooling water in cooling tower and diluting boiled down cooling water. Although it also depends on power generation capacity, since a large amount of water is required, securing water for binary geothermal power generation is next in line after finding a suitable geothermal spot in terms of importance.

At the Goiyuen Geothermal Power Station, we use spring water and mountain water. Yuyama Geothermal Power Plant uses well water and surface water.

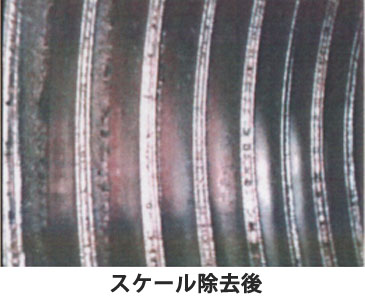

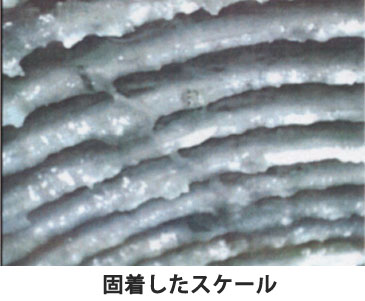

The cooling water pressure loss in the condenser (the pressure difference at the cooling water inlet / outlet) started to increase about 6 months after the start of power generation. The power generation capacity was reduced due to crystallization dissolving in cooling water. As the cooling water evaporates, the calcium and silica components dissolved in the vapour are concentrated, increasing the numerical value of conductivity and promoting crystallization process.

A chemical solution for suppressing components causing crystallization was injected further chemical treatment was carried out. Since the chemical costs about 1.5 million yen (tax excluding tax, per power plant) and takes up a high proportion of maintenance cost, the planning stage should also account for this in advance.

There is also a need for a blowing device for monitoring and diluting the conductivity of cooling water boiled down by evaporation. Approximately 2.0 L of water is needed for blowing once, and running cost is increased if this is replenished with tap water. Thus, it is necessary to compare with the initial cost and assessing water resources carefully.

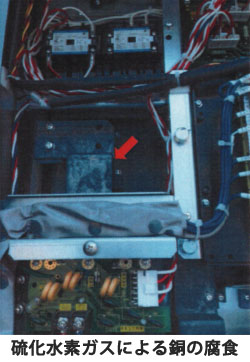

Volcanic gas (hydrogen sulfide gas)

Hydrogen sulfide and sulfur dioxide contained in volcanic gases corrode copper used for wires and terminals, which can cause failure and disconnection of generators and cubicles. The existence of hot spring component gas with high humidity for geothermal power generation is inevitable, so as a countermeasure, vaporizable anticorrosive material was installed in generator units or cubicles which are at high risk of corrosion. However, the hydrogen sulfide gas concentration was higher than expected (300 ppb) and corrosion of copper progressed. As a result, the generator broke down in less than a year and operation had to be suspended. Based on the rationale that it would be better not to expose components to air containing corrosive gas, we proceeded to plate copper band with tin and seal equipment with tape. In the future, more measures to prevent corrosion are necessary.

Other measures against natural disasters

Some natural disasters that we are most wary of are heavy rain, lightning strikes, earthquakes and volcanic activities. At the design stage, the possibility of landslides and landslides caused by typhoons need to be considered when selecting site location. Although Oita prefecture’s the number of thunderstorm days of the year are 19th in the country and lightning countermeasures are not particularly applied, depending on the location, measures such as installing lightning rods might be necessary. Earthquakes and volcanic activities have inherent influence on the nature of geothermal power generation. In particular, the change in the amount of steam within geothermal reservoir due to volcanic activities could decide the existence / nonexistence of power generation. Although we have a lot of concern over this matter, there is nothing much to be done as we have no control over the forces of nature. In dealing with earthquakes, it is necessary to consider how much seismic intensity can be tolerated at the time of planning. Luckily, there was no damage to the power station when the seismic intensity 4 earthquake hit in July 2015.

Future tasks

Although this is a geothermal power generation project that aims for local production and consumption of energy, there remains many obstacles to overcome.

In addition to the problems listed above, we are still facing difficulties in negotiating purchase price and purchase period with electricity utilities companies. Since this issue is linked to the survival of the project and we would like to ask the administrative for further support. In addition, as another method to elevate the problems of lower the power generation output in the summer and high maintenance costs, we hope to explore research on applying a multi-stage cascade system for hot water usage after power generation.